What Is Stainless Steel Vacuum Flask

A vessel container jug made by double walls of stainless steel with vacuum sealed insulated layer between the double walls to keep water beverage ice cold for 24 hours and hot for 12 hours without condensation issue on the outer wall is called Stainless Steel Vacuum Flask.

How It Works

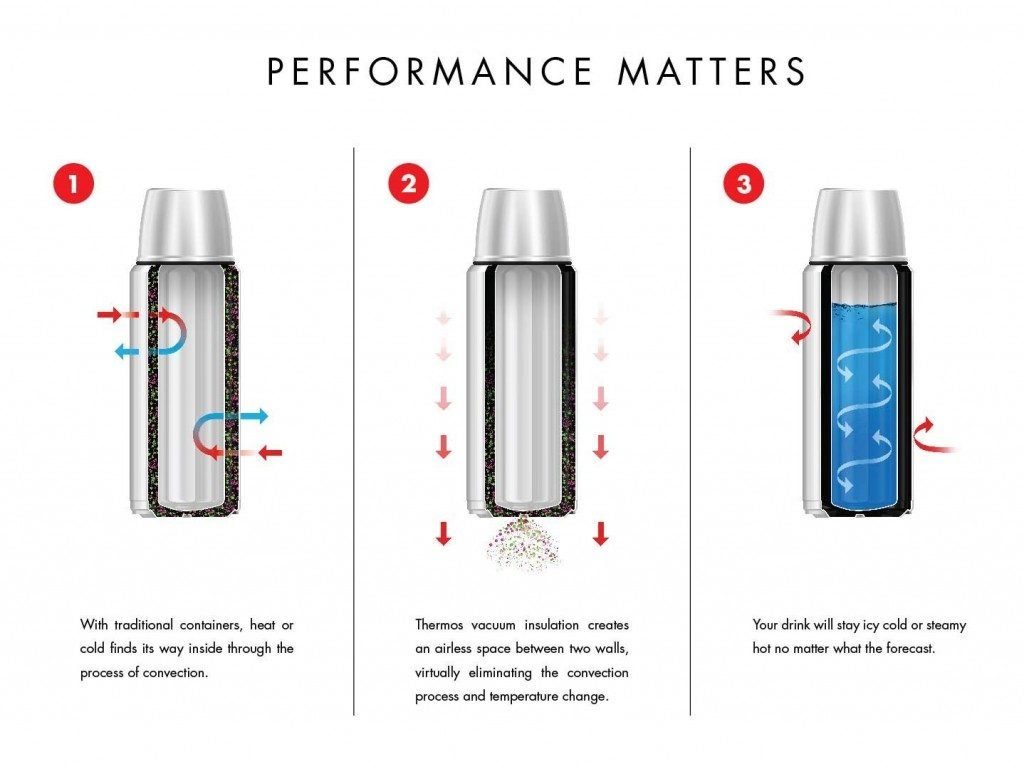

For a traditional container like a plastic bottle, heat or cold finds its way inside through the process of convection.

The vacuum layer of vacuum flask can stop heat conduction from outside to inside, and inside to outside, because heat/air can not flow in the vacuum space. Therefore, the convection process inside the flask is halted and the temperature remained.

Your drink will stay ice cold or steady hot in all weathers.

How to Make It?

- Purchasing raw material

- Cutting stainless steel pipes

- Water expansion or stretching process to fabricate outer shell and inner shell

- Cutting pipes to into 2 pieces

- Mouth forming and threading

- Shrinking bottom

- Matching and welding the mouth of stainless steel vacuum flask (the out wall and inner wall join together then do Laser welding)

- Fine tune the mouth

- Bottom punching and matching

- Fine tune the bottom

- Rolling up the corners

- Flatting the inner shell top side

- Thread rolling

- Cleaning and drying

- Appearance inspection

- Joint welding

- Waterproof test and leak detection

- Matching cup mouth

- Welding bottom

- Spot welding

- Pressing the match

- Welding inspection of the bottom

- Vacuuming process inside the vacuuming equipment about 4 hours to create vacuum insulated layer between the inner wall and outer wall

- Vacuum insulation performance inspection (Vacuum Insulation Test (measure the stainless steel bottle tumbler is good quality or faulty on vacuum insulation) 100%)

- Electrolysis for the inside of the stainless steel vacuum insulated flask (it can clean the dirty to have nice surface, also create a layer on the inner surface to have good corrosion prevention)

- Inspection of electrolysis quality

- Polishing the surface of outer wall of the stainless steel insulated flask

- Second time fully vacuum insulation test

- Decoration of spray painting or powder coating or transfer printing

- Inspection of spray painting & powder coating

- Laser engraving customized logo / silk screen logo

- Third time 100% vacuum insulation test for each insulated bottle/tumbler/cup

- Assembling with caps and other attachments such as straws, carabiners, and brushes.

- Perform quality inspection

- Packaging

How Much Does It Cost to Make It

When you need to create a custom design stainless steel vacuum flask, you need to know How Much does it cost for manufacturing? and what can affect the cost?

In this situation, you are in the right place here that we Ecoshine Drinkware Limited can help you to find out the important things you should know about Stainless Steel Vacuum Flask Manufacturing prices costs.

The stainless steel vacuum flask cost can be varied, which depends on the custom parts design and the order quantities.

There are some basic information of stainless steel flask pricing that you need to know. For example, product design cost will begin when you set up the project even the production has not been started; the material not only affect the quality but also is the main cost of your custom vacuum flask products; the order quantities could affect a large part of the whole cost and affect the shipment cost for your water bottle products;

You also need to think about:

- The timing of your order

- The cost of using surface treatment

- Labor costs

- Any additional cost such as packing cost, shipment cost

To understand more, Read More to know each of the things that affect Stainless Steel Vacuum Flask pricing…..

![CTA-post[1] CTA-post[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/CTA-post1-pinc8qifoykue8cii862f8ijwusnp1nxmra8d0ul46.png)

![Single-wall-amp-double-wall-stainless-steel-bottle-02[1] Single-wall-amp-double-wall-stainless-steel-bottle-02[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/Single-wall-amp-double-wall-stainless-steel-bottle-021-pinc8qie653avq5chl33s4ylm6j4dcnaa0jro9r22s.jpg)