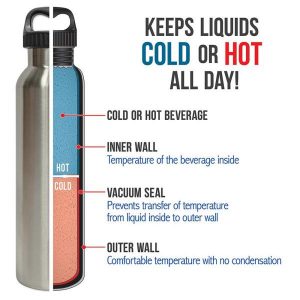

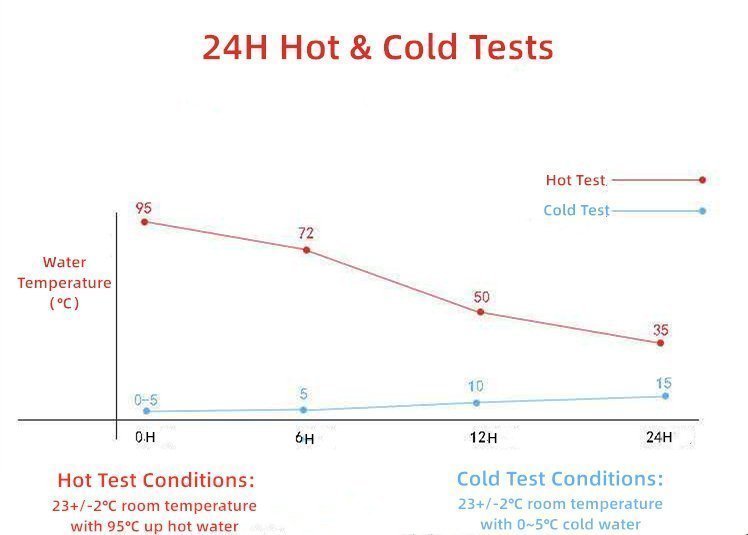

A metal thermos flask, usually made by stainless steel material, has double walls structure and a vacuum insulated layer between the double walls to keep drinks ice cold for 24 hours and hot for 12 hours.

How A Thermos Flask Works

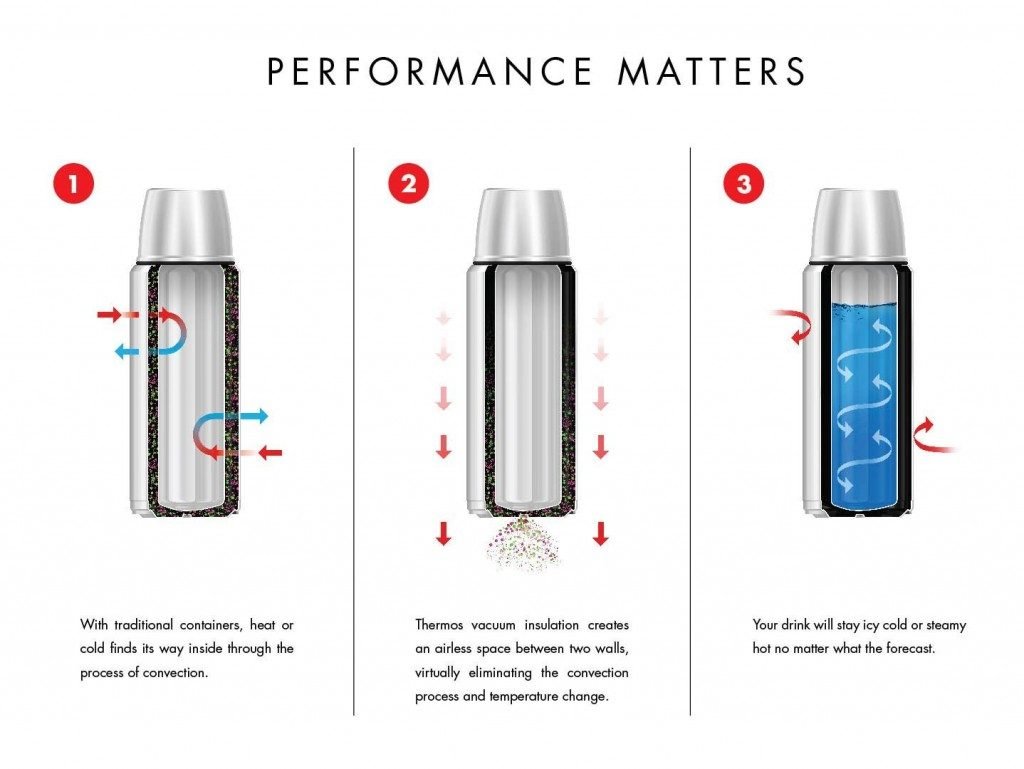

1. With traditional containers, heat or cold finds its way inside through the process of convection, no matter the container is single wall or double walls.

2. Metal thermos has a vacuum insulation which is an airless space between the double walls, virtually eliminating the convection process and temperature change, heat or cold can’t go through the airless space.

3. Your drink will stay ice cold or steamy hot no matter what the forecast and environment being.

How Long Metal Thermos Flask Can Keeps Hot Or Cold?

There are some major elements that would affect the timing of metal thermos to keep drinks ice cold and hot:

- The sizes/volume of the metal thermos bottle. With a large volume, there is more heat or cold energy in the container, which will allow the heat or ice to be held longer.

- The size of opening mouth. The smaller opening will eliminate the space for heat to escape from the mouth of the metal thermos.

- The CAP/LID designs. Different designs of lids will change the transfer of heat through the lid to the outside, and Tempshield lids will help with insulation performance.

- Manufacturing, technique, quality criteria etc.

How Is Metal Thermos Flask Made?

- Purchasing raw material

- Cutting stainless steel pipes

- Water expansion or stretching process to fabricate outer shell and inner shell

- Cutting pipes to into 2 pieces

- Mouth forming and threading

- Shrinking bottom

- Matching and welding the mouth of stainless steel vacuum flask (the out wall and inner wall join together then do Laser welding)

- Fine tune the mouth

- Bottom punching and matching

- Fine tune the bottom

- Rolling up the corners

- Flatting the inner shell top side

- Thread rolling

- Cleaning and drying

- Appearance inspection

- Joint welding

- Waterproof test and leak detection

- Matching cup mouth

- Welding bottom

- Spot welding

- Pressing the match

- Welding inspection of the bottom

- Vacuuming process inside the vacuuming equipment about 4 hours to create vacuum insulated layer between the inner wall and outer wall

- Vacuum insulation performance inspection (Vacuum Insulation Test (measure the stainless steel bottle tumbler is good quality or faulty on vacuum insulation) 100%)

- Electrolysis for the inside of the stainless steel vacuum insulated flask (it can clean the dirty to have nice surface, also create a layer on the inner surface to have good corrosion prevention)

- Inspection of electrolysis quality

- Polishing the surface of outer wall of the stainless steel insulated flask

- Second time fully vacuum insulation test

- Decoration of spray painting or powder coating or transfer printing

- Inspection of spray painting & powder coating

- Laser engraving customized logo / silk screen logo

- Third time 100% vacuum insulation test for each insulated bottle/tumbler/cup

- Assembling with caps and other attachments such as straws, carabiners, and brushes.

- Perform quality inspection

- Packaging

How to Clean A Stainless Steel Thermos Flask

When you have smell or rust (corrosion) problem with your thermos flask, you can use vinegar to clean and sterilize the inside of the thermos bottle, which will help you to completely remove rust and get the smell out of your thermos flask.

What Ecoshine Drinkware does?

The year 2009 witnessed the founding of Ecoshine Drinkware Limited in Wuyi County, Zhejiang Province, China. And since then, our company began to serve as a custom design water bottle manufacturer, providing customers of private brands with a variety of personalized bottles. We have been and will always be devoted to concept design of ingenuity, tooling development of high-tech and inspection of meticulousness. We cling to the belief that it is our dedication to these three slogans as well as our premium products that help us win customers’ satisfaction, trust and loyalty, which in turn enables our company to progress steadily and swiftly. We have expanded our business during the past 10+ years and now we also include OEM manufacturing of stainless steel water bottles / tumbler cups / travel mugs / pet bowls / food containers / vacuum flasks / beer growlers /.Though young and small, our company has a production facility of 8,000 m2 and yields a monthly output of 250,000 pcs. We are eager to obtain your contact and wish we can establish long-term business relationships.

![CTA-post[1] CTA-post[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/CTA-post1-pinc8qifoykue8cii862f8ijwusnp1nxmra8d0ul46.png)

![Single-wall-amp-double-wall-stainless-steel-bottle-02[1] Single-wall-amp-double-wall-stainless-steel-bottle-02[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/Single-wall-amp-double-wall-stainless-steel-bottle-021-pinc8qie653avq5chl33s4ylm6j4dcnaa0jro9r22s.jpg)