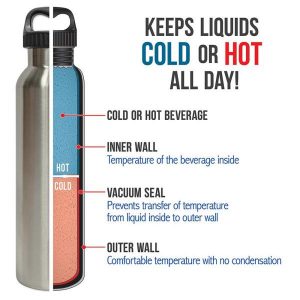

A stainless steel water bottle is a container which has double walls structure with a vacuum insulated layer that is used to hold liquids or other beverages and keep them hot for 12 hours and ice cold for up to 24 hours. An insulated water bottle allows an individual to drink and transport a beverage from one place to another without losing temperature inside and with No Condensation on the bottle surface.

Background? How Insulated Water Bottles Works?

Most of the people would ask how does an insulated stainless steel water bottle work to keep hot liquids hot and cold liquids cold?

The answer is with a vacuum insulated layer between the double walls of stainless steel shells, the heat and air transferring from inside to outside or outside to inside can be stopped.

History? of Stainless Steel Water Bottles?

The first known bottles, made of glass, were produced in about 1500 B.C. by the Egyptians. The bottles were formed by placing molten glass around a core of sand and clay. The core was then dug out once the glass cooled. The process of making bottles was time-consuming and complex, so they were considered a luxury item in ancient Egypt. By 200 B.C. , glass bottles were made in China and Persia, as well as Egypt where the molten glass was blown into a mold. The Romans later adopted this same method and the technique was spread throughout Europe during the 1400s and 1500s. The first bottle- and glass-making factory in the United States was established in Virginia in 1608.

Read more: http://www.madehow.com/Volume-4/Insulated-Bottle.html#ixzz6o13jHjKA

Today, the most popular insulated bottle is Stainless Steel Insulated Water Bottle,which is customized, durable, reusable and eco-friendly.

Raw Material? of Stainless Steel Water Bottles?

The primary raw materials used in the manufacture of the insulated bottle are stainless steel, which form the outer and inner part of a cup.

In the production manufacturing process, the vacuum insulated layer between two double walls (inner cup & outer cup) is produced.

The top cap of the insulated bottle can be made with Plastic, Silicone or Stainless Steel.

There must have soft silicone seal to prevent leaking on the bottle mouth opening.

The Manufacturing Process? of Insulated Stainless Steel Water Bottles?

- Purchase raw material

- Cutting stainless steel tube

- Shape forming with water swelling (or deep drawing forming)

- Cutting into 2 pieces

- Mouth forming with threads

- Matching and welding the mouth of stainless steel flask (the out wall and inner wall join together then do Laser welding)

- Welding the bottom cap and with an attachment of Getter

- Vacuum process inside the vacuum machine is about 4 hours, creating vacuum insulated layer between the double walls stainless steel

- Vacuum Test (measure the stainless steel vacuum flask to see whether it is of good quality or faulty on vacuum insulation) 100%

- Electrolysis for the inside of the stainless steel vacuum insulated flask (it can clean the dirty to have nice surface, also create a layer on the inner surface to have good corrosion prevention)

- Inspection of electrolysis quality 100%

- Polishing the surface of outer wall of the stainless steel insulated flask

- Inspection of Polishing quality 100%

- Vacuum insulation test 100% second time

- Decoration (spray painting, powder coating, water transfer painting, heat transfer printing, logo printing or laser engraving etc.)

- Assembly with caps, cleaning, inspection, packaging

- Perform final QC inspection

Quality Control? of Insulated Stainless Steel Water Bottles?

- Drop Test

- Leaking Test

- Material Test

- Corrosion Test

- Vacuum Insulation

- Heat retention

- Color matching

- Printing scratch test

- Cosmetic inspection

The Future? of Insulated Stainless Steel Water Bottles?

- Metal water bottles are growing in popularity. Made primarily from stainless steel or aluminium (aluminum), they are durable, retain less odor and taste from previous contents than most plastic bottles, but can sometime impart a metallic taste. Metal bottles thus often contain a resin or epoxy liner to protect contents from taste and odor transfer or corrosion.[3] Although most liners are now BPA-free, older and less expensive models can contain BPA. Glass liners may also be used (see next subsection).It is not recommended to fill aluminium bottles with acidic liquids (e.g. orange juice), as this could cause aluminium to leach into the contents of the bottle.[4] Depending on the type of source material and manufacturing process behind a stainless steel bottle, trace amounts of minerals can leach into contents from this type of bottle as well.[5] Stainless steel bottles that do not contain a liner have been known to transfer a rusty taste and odor to contents. Bottles made with food-grade stainless steel (grade 304, also known as 18/8) do not transfer taste or odor.Metal (especially steel) water bottles can be heavier than their plastic counterparts. Single-walled metal bottles readily transfer temperature of contents to external surfaces, which makes them unsuitable for use with unusually hot or cold liquids. Double-walled metal bottles are insulated to keep cold liquids cold and hot liquids hot, without the external surface being too hot or too cold. Because double-walled bottles have more metal in them, they are more expensive. They are typically vacuum-insulated, but some may have a solid or gel insulation between the metal walls.

![CTA-post[1] CTA-post[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/CTA-post1-pinc8qifoykue8cii862f8ijwusnp1nxmra8d0ul46.png)

![Single-wall-amp-double-wall-stainless-steel-bottle-02[1] Single-wall-amp-double-wall-stainless-steel-bottle-02[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/Single-wall-amp-double-wall-stainless-steel-bottle-021-pinc8qie653avq5chl33s4ylm6j4dcnaa0jro9r22s.jpg)