What Is Stainless Steel Cup?

A cup that is made by stainless steel 18-8 usually has a single wall or double walls structure with different sizes from 6oz to 64oz to meet your different needs such as drinking water, beer, coffee, soda etc.

What’s the Difference Between Single Wall And Double Walls?

The single wall stainless steel mug is suitable for drinking water, beer and coffee anywhere, but it is not able to keep drinks hot or cold when exposed to heat or cold outside and cannot be drunk slowly.

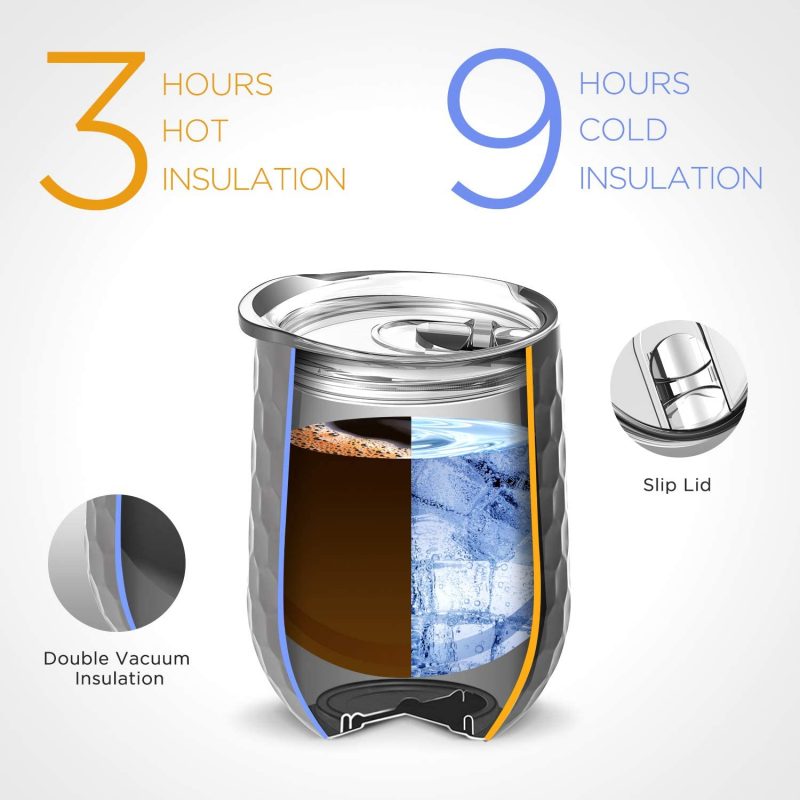

The double walls stainless steel cups have a vacuum insulated layer between the double walls to keeps drinks ice cold and hot hours for your drinking anywhere.

- Purchasing raw material

- Cutting stainless steel pipes

- Water expansion or stretching process to fabricate outer shell and inner shell

- Cutting pipes to into 2 pieces

- Mouth forming and threading

- Shrinking bottom

- Matching and welding the mouth of stainless steel vacuum flask (the out wall and inner wall join together then do Laser welding)

- Fine tune the mouth

- Bottom punching and matching

- Fine tune the bottom

- Rolling up the corners

- Flatting the inner shell top side

- Thread rolling

- Cleaning and drying

- Appearance inspection

- Joint welding

- Waterproof test and leak detection

- Matching cup mouth

- Welding bottom

- Spot welding

- Pressing the match

- Welding inspection of the bottom

- Vacuuming process inside the vacuuming equipment about 4 hours to create vacuum insulated layer between the inner wall and outer wall

- Vacuum insulation performance inspection (Vacuum Insulation Test (measure the stainless steel bottle tumbler is good quality or faulty on vacuum insulation) 100%)

- Electrolysis for the inside of the stainless steel vacuum insulated flask (it can clean the dirty to have nice surface, also create a layer on the inner surface to have good corrosion prevention)

- Inspection of electrolysis quality

- Polishing the surface of outer wall of the stainless steel insulated flask

- Second time fully vacuum insulation test

- Decoration of spray painting or powder coating or transfer printing

- Inspection of spray painting & powder coating

- Laser engraving customized logo / silk screen logo

- Third time 100% vacuum insulation test for each insulated bottle/tumbler/cup

- Assembling with caps and other attachments such as straws, carabiners, and brushes.

- Perform quality inspection

- Packaging

![CTA-post[1] CTA-post[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/CTA-post1-pinc8qifoykue8cii862f8ijwusnp1nxmra8d0ul46.png)

![Single-wall-amp-double-wall-stainless-steel-bottle-02[1] Single-wall-amp-double-wall-stainless-steel-bottle-02[1]](https://www.ecoshinedrinkware.com/wp-content/uploads/elementor/thumbs/Single-wall-amp-double-wall-stainless-steel-bottle-021-pinc8qie653avq5chl33s4ylm6j4dcnaa0jro9r22s.jpg)